Heat Exchangers

Water heating systems that will meet your tough demands, day after day.

Whether your energy source is steam, hot water, or electricity, Reyco Sales has the right product for your application. We invite you to find out more about our complete line of heat exchangers, tanks, and packaged water heaters available in single and double wall configuration.

Cemline

CEMLINE CORPORATION ® has manufactured tanks, pressure vessels, packaged water heaters, unfired steam clean generators, and replacement tube bundles to suit customer requirements since 1935. Our products are used for the storing and heating of water and liquids in plumbing and heating systems and industrial processes.

Unfired Steam Generators

CEMLINE® Unfired Steam Generators are designed to produce clean steam with steam or high temperature hot water as an energy source for use where there is a need to produce clean steam from boiler steam or high temperature hot water.

Water Heaters - Instantaneous and Semi-Instantaneous

A full line of water heaters that offer the perfect solution for any type of installation:

- where space is at a premium

- large capacity needs

- work in conjunction with condensing or speciality hydronic boilers

- for remote locations not requiring electricity

- solar powered

Cement Lined Storage Tanks

A STONESTEEL® Tank is constructed with a steel shell which completely supports a uniform, water-resistant lining of hydraulic STONESTEEL®. The rusting and corrosion common with steel tanks is prevented because the water touches only non-corrosive surfaces. The STONESTEEL® is applied in a continuous arch against the metal wall and will not be injured by ordinary use or handling.

Steel Tanks

CEMLINE Steel Tanks are manufactured in strict accordance with ASME code requirements and National Board Registration. Non-Code tanks are also available.CEMLINE Steel Tanks can be built in accordance with working pressures designed to suit particular jobs. Tanks are usually built 125 psig working pressure, but tanks with working pressure from 0 to 500 psig can be provided.

Condensate Coolers

Cemline Blowdown / Condensate Coolers are designed to receive blowdown from a steam boiler, flash the blowdown to steam, and cool the condensate going to drain.

Buffer Tanks – Chilled Water

CEMLINE® Chilled Water Buffer Tanks (CWB) are designed to be used with chillers which do not have water volumes of sufficient size in relation to the chiller. The insufficiently sized systems do not have enough buffer capacity for the chilled water causing poor temperature control, erratic system operation and excessive compressor cycling.

Buffer Tanks – Hydronic Boiler Systems

Cemline primary/secondary buffer tanks improve system efficiency by preventing the problem of short cycling boiler(s). Low water content boilers operating at low loads will short cycle leading to sooting, premature component failure, and nuisance shut-downs. If the boiler is allowed to fire for a minimum of several minutes the full efficiency of the boiler can be achieved preventing sooting, premature

Flash Tanks

EMLINE Flash Tanks are used to flash steam from high temperature condensate prior to introducing into low pressure lines and to flash condensate prior to returning to the boiler or condensate tank. CEMLINE Flash Tanks are ASME code constructed and stamped for 150 PSI working pressure of carbon steel and have a prime painted exterior. Vessels are registered with the National Board.

Boiler Blowdown Tanks

CEMLINE® blow down/condensate coolers are designed to receive blow down from a steam boiler, flash the blowdown to steam, and cool the condensate going to drain. CEMLINE Blow Down/Condensate Coolers are ASME code constructed and stamped for 150 PSI working pressure. Minimum Steel thickness is 3/16″ where conditions require these vessels to be constructed with 1/4″, 3/8″ or ½” steel thickness.

The blow down enters the tangential inlet where it meets a 90 degree stainless steel wear plate. The wear plate will prevent erosion of the side wall of the vessel. The tangential blow down entry causes the blow down to swirl around the circumference of the vessel where part of the liquid will flash to steam and the balance will settle to the bottom. The internal flash will go through the vent to atmosphere and the hot condensate and sludge will fall to the bottom where it will flow by gravity to the drain leg.

The temperature of the condensate will activate the thermal control valve which will feed cold water into the drain leg where the cold water and hot condensate will mix. This results in drained liquid temperature which is acceptable for municipal sewage. The Blow down vessel is available without the condensate cooling leg.

Replacement Tube Bundles

CEMLINE® Replacement Tube Bundles for Storage Water Heaters and Heat Exchangers

Cemline builds Replacement Tube Bundles as exact replacement for all existing tube bundles. The Replacement Tube Bundles are readily available with standard 1 week shipment. Replacements available for Steam, Boiler Water, and High Temperature Hot Water Bundles.

Cemline standard replacement tube bundles are designed for a maximum working pressure of 150 psig and a temperature of 375 oF.

More Information

For more information about Cemline Heat Exchanger Products, click here to visit their website or contact us.

AIC

AIC Heat Exchangers is the premier manufacturer of speciality heat exchangers in Canada.

Advanced Industrial Components

AIC is a manufacturer of heat exchangers and custom designed heat transfer, and heat recovery products.

AIC values engineering excellence. Their strengths lie in the high quality and fine craftsmanship of our products, the engineering expertise of our team, and our quest to continuously develop technologically new and exciting products. AIC’s diverse product offerings are installed worldwide.

Please visit the website to see all the products.

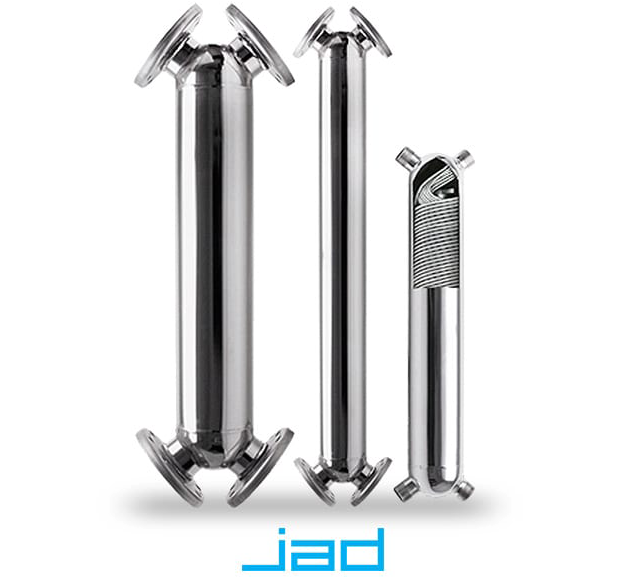

JAD Line Heat Exchangers

Stainless Steel Shell and Coil Heat Exchangers

JAD shell & coil heat exchangers are distinctly characterized by their angular connections, and by the circular layers of helically corrugated tubes within the shell. This unique design optimizes the performance and heat transfer efficiency of the units.

This line of heat exchangers is primarily designed for vertical installations. Combined with their compact size, the JAD heat exchangers can be installed in virtually any application where space is a constraint.

Applications

- Heating systems

- Chilled water systems

- Groundwater systems

- Residential use

Larger models of the shell and coil heat exchangers are designed to different parameters.

More Information

For more information about AIC Heat Exchanger Products, click here to visit their website or contact us.